The buzz of chainsaws in the bush, the bang of hammers on chisels, the smell of fresh cut cedar and the camaraderie of men and women fill the air in a Gabriola Island neighbourhood. These are the sights, smells and sounds found year round at the Island School of Building Arts. The school’s construction site is visible from the rural mailbox on the corner. Neighbours and curious visitors can watch the progress of student projects as they rise up amongst the trees that surround the site. A nearby beach provides an opportunity for students to discover secret treasures; logs washed up on shore become potential building materials.

In January 1998, 11 students, ranging from interested beginners to experienced carpenters, attended the Island School of Building Arts to learn the art and craft of modular post and beam construction. Their project was the assembly of a 1,000 sq. foot red cedar frame home. During the fall ’97 course, students laid out and cut most of the mortise and tenon joinery for the upright posts and horizontal beams. The new students still had a lot to do, including joinery work, building a temporary foundation and assembling all the pieces of the frame.

The winter ’98 students learned the building’s grid design and reviewed the function of the various types of joinery during the first two days. James Mitchell, the Island School of Building Arts owner and teacher, demonstrated the operation of all the power tools and thoroughly explained the safety rules. On the third day, after early morning stretches and coffee, students headed down to the site and began sorting out the stored timbers and working with the materials and tools. One week later, the bottom beams, the posts and most of the sill beams were in place.

Everything Doesn’t Always Go As Planned

The joinery for the top sill beam was finished in the fall ’97 course, but compensation for a miscut joint made this beam a challenge for the winter ’98 students. “It wasn’t fitting right and we knew something was wrong with it. We discussed and debated how to solve the problem.” In an attempt to make it fit, the beam was cut. Unfortunately, it was now too short. “We should have waited for James’ go-ahead, but we were eager to show we had learned something,” admitted some of the students.

The first lesson of carpentry was learned once again; measure twice, cut once. The problem: a misfit and no more timber to work with. The solution: cut down a 30-foot fir tree from Mitchell’s property and mill it in the bush using chainsaws. “It took 10 of us to haul it out of there, but it fits perfectly,” said Roger Berrett, speaking proudly of the building’s top supporting beam.

Mitchell avoids using expensive industrial tools that are inaccessible to the average owner-builder. His students assembled the 1,000 sq. foot home using hammers, sharp chisels, chainsaws, circular saws, planers, sanders, drills, tape measures and sharpened pencils. All joinery work is done using templates and these basic tools. Each cut piece fits snugly into the other and is held in place by handmade wood pegs. “It fits together like a great big Meccano set,” says Mitchell, using his favourite metaphor. The wood-pegged joinery creates a functional, impressive and sturdy post and beam home. This modular system allows the house to be disassembled piece by piece and then relocated, expanded or redesigned.

A question in the minds of many students is: “Could I build this house by myself?” Mitchell believes it is possible. With the right tools and instruction, anyone can build a beautiful home. “It does help to have strong neighbours when it comes to lifting the timbers into place,” he adds. During the two-week to two-month courses, students also learn the school’s philosophy of debt-free housing. “It is possible for people to build their own homes and not have to go into debt, to use their own sweat-equity, natural and recycled materials that look good and will stand the test of time,” says Mitchell in his book, The Art and Craft of Modular Post and Beam Construction. A thousand dollars will buy the first timbers and you can begin to build.

With the right tools and instruction, anyone can build a beautiful home.

If the materials are stored in a dry place and the cut ends sealed, you can work at your own pace for years. Your budget, ingenuity and personal preference, as well as building codes, help to determine the materials for the walls. “I had been conditioned to believe that real building materials came from building stores… I had never imagined the variety of natural materials available and the ways they could be used for building,” says Mitchell, also an advocate of alternative building methods. He encourages students to discover what is available around them when planning their structures. Straw bale, adobe, brick, rammed earth, log, stresskin panels or studs, plywood and insulation are possible wall systems for post and beam frames.

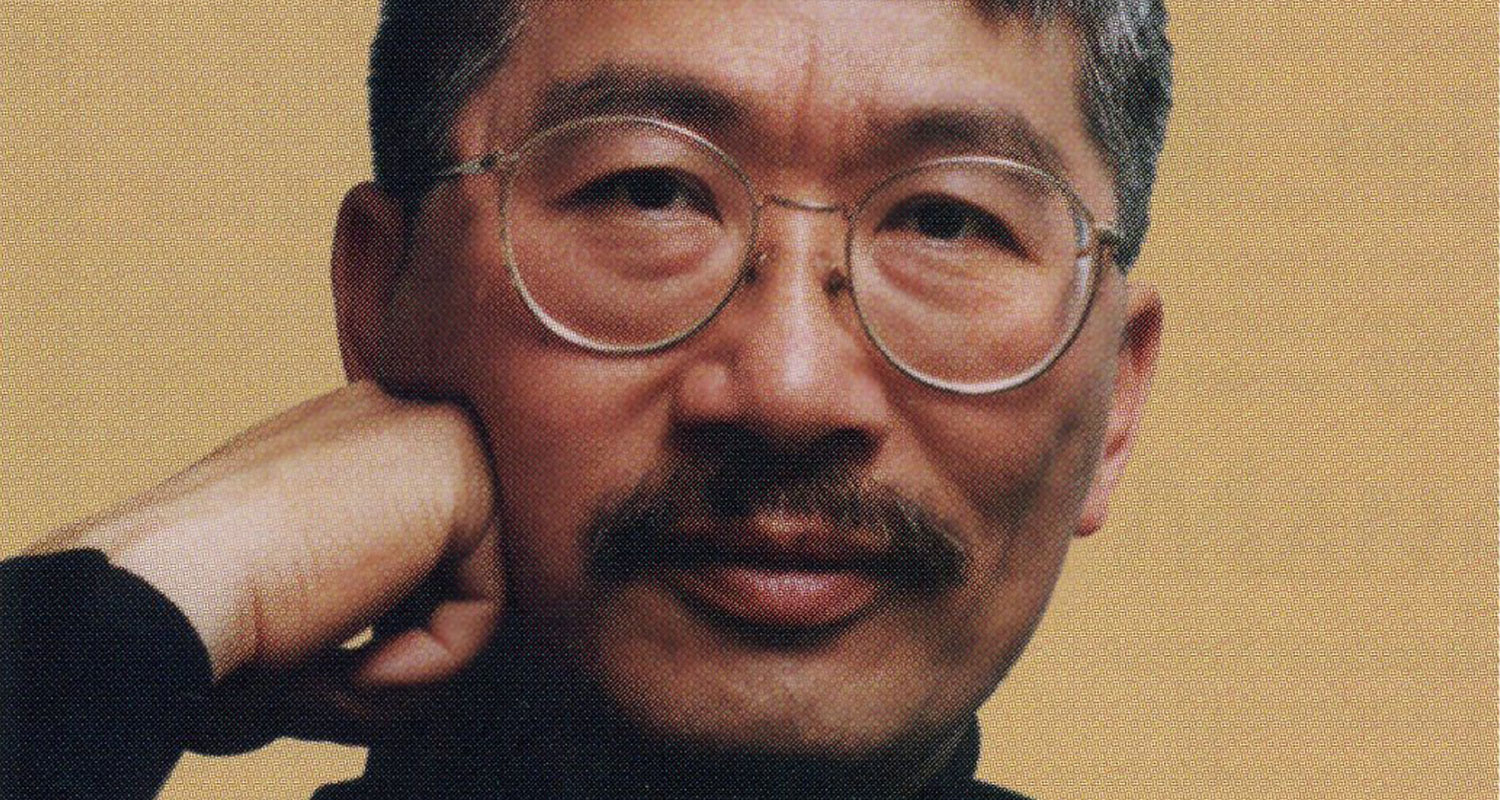

James Mitchell’s Experience

Mitchell has been building houses of one kind or another for over 20 years, and if you include the wood, sand, snow and straw forts he built as a child, he has been developing his skills and style throughout his life. Mitchell’s 4,000 sq. foot home, office, workshop and studio are a testament to what is possible with modular post and beam construction. He pre-built the structural components of his house three years before buying the land on Gabriola Island, and assembled the frame within four months on a permanent foundation. The cozy bedroom on the top level of the house was built, deconstructed and rebuilt three times prior to arriving at its present location. “I could easily take this apart in a day. It’s like a big jigsaw puzzle,” says Mitchell proudly. He also integrated various recycled and salvaged materials into his home: the windows came from a bank in Vancouver, the hardwood floors rescued from a gymnasium and the sleek kitchen counters salvaged from a movie set.

At the Island School of Building Arts, students dressed in dusty jeans, tool belts and cedar-shaving covered shirts, learn the basics of post and beam construction. They witness the beauty and functionality of recycled building materials, and feel the satisfaction of watching a home grow up before them. The course format permits each student to learn at his or her own pace, and the small class size ensures that everyone gets personal instruction. Mitchell’s passion for building, his years of teaching experience and his easygoing, confident and relaxed nature create an open and fun learning environment.

The Island School of Building Arts offers a wide variety of building projects and course schedules. You can find more photographs of the building projects and information about the school and James Mitchell if you visit The Island School of Building Arts